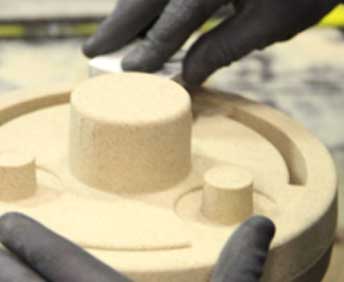

Fully equipped lab for inspection of incoming resin-coated sand.

Critical To Quality [CTQ] parameters like Core-box Temperature & Curing Time are interlocked on Core Shooters designed & implemented by our engineers at our sub contractors.

Experienced team for producing very delicate sand cores for critical components.

We have allotted core shooter machines to our vendor, who’s core strength is fulfilling our target quantities.

Stringent inward inspections of aluminum alloy raw materials involve spectro analysis, Confirmatory furnace melting is an additional step done only if required.

Raw material traceability with supplier code & heat number identification and First-In-First-Out (FIFO) followed at all stages. Alloy suppliers are periodically rated for their quality and delivery performance through our “Supplier Quality Assurance”. Can arrange for wide range of Aluminium alloys with separate melting furnaces for all alloys.

Molten metal treatments like nitrogen degassing and fluxing are backed up by density index testing facility for checking its effectiveness.

Microstructures analysis of alloys is carried out. Mechanical properties of all incoming alloys tested periodically. Keeping records for at least 3 years for transparency and track ability

Highly experienced die casting operations team, possessing excellent knowledge in producing complex castings, handling different alloys, and more. A wide variety of complex components with wall thicknesses down to 4 mm and with hollow profiles.

Using the technology (90 degree adjustable) of tilted gravity die casting or permanent mold casting, the melt is poured under the influence of gravity through a gating system into the mold. The shrinkage porosity is absorbed by the feeder and overflow system, and the solidification is directed through cooling the mold.

Stringent controls with process parameters like Metal Temperature, Die Temperature & Hydraulic Oil Temperature, are interlocked with auto / semi auto-cycle of the machine designed & implemented by our engineers. We able to reach a high production capacity for gravity casting, offering our customers a flexible approach to volumes and alloys. We are always careful to fulfill our customer’s technical, mechanical and aesthetic specifications, keeping costs low and offering high quality goods.

Highly experienced die casting operations team, possessing excellent knowledge in producing complex castings, handling different alloys, and more. A wide variety of complex components with wall thicknesses down to 4 mm and with hollow profiles.

Using the technology (90 degree adjustable) of tilted gravity die casting or permanent mold casting, the melt is poured under the influence of gravity through a gating system into the mold. The shrinkage porosity is absorbed by the feeder and overflow system, and the solidification is directed through cooling the mold.

Stringent controls with process parameters like Metal Temperature, Die Temperature & Hydraulic Oil Temperature, are interlocked with auto / semi auto-cycle of the machine designed & implemented by our engineers. We able to reach a high production capacity for gravity casting, offering our customers a flexible approach to volumes and alloys. We are always careful to fulfill our customer’s technical, mechanical and aesthetic specifications, keeping costs low and offering high quality goods.

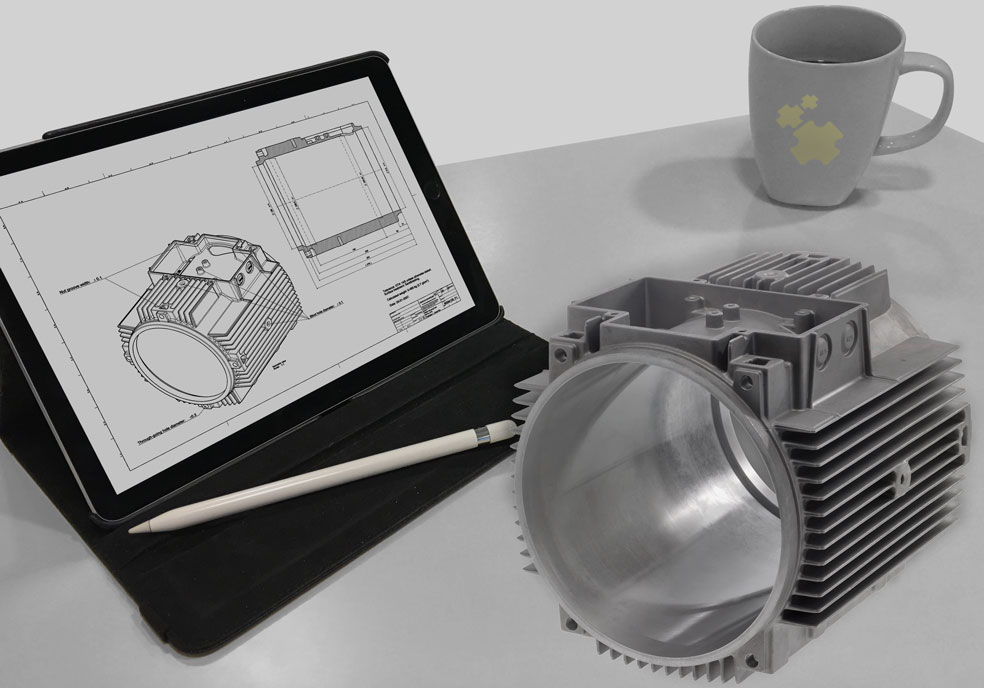

Enter our world of precision craftsmanship, where each product is born with a commitment to perfection. By nurturing excellence through precise engineering, our foundry strives for professionalism, ensuring outstanding results in line with high industry standards. Visit us to Noble Foundry, where we unveil our state-of-the-art technologies and machinery, the beating heart of our production

Aluminum is used in Gravity Die casting processes because of its dimensional stability in complex shapes. It also withstands high operating temperatures and offers corrosion resistance and versatility

The initial step in gravity die-casting involves the preparation of the alloy, incorporating a combination of aluminum and other metallic or non-metallic additives such as metal alloys, silicon, magnesium, etc. The alloy is selected based on the requirements of the final product and the desired properties. The aluminum alloys we use include: LM6, LM9, LM20, LM24, LM25 etc

Experienced team of die maintenance engineers.

Die unloading reports along with last shot of every setup maintained with die history cards.

Out source tool room facility is well-equipped with VMC having CAD/CAM.

T6 heat treatment in Continuous Type Furnace with SCADA control & a Drop Bottom Quench Furnace followed results in a precisely controlled and rapid quenching process for improved mechanical properties of the workpiece. Due to the low porosities, we achieve high mechanical properties over a heat treatment.

Out source powder coating plant with 7 tank pre-treatment processes. Fully equipped testing lab having facilities like testing of pre-treatment chemicals, testing of powder coated components for Dry film Thickness, Salt spray test, Humidity test, etc. Globally renowned suppliers for Powder and Pre-treatment chemicals like Henkel, Kansai Nerolac, BSF and many more.